Performance and Innovation

Optical Thin Film Technology

Here to view our Optical Filters

What is optical thin film technology?

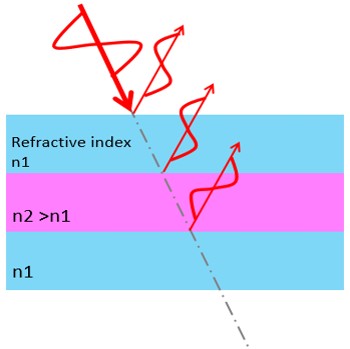

Figure 1. multi-layers of thin-films of refractive indice n1, n2

Optical multi-layers of thin-films make it possible to enhance or to reduce reflected light at a surface by using two refractive indice materials n1 and n2. (Fig. 1) The former is well known as high reflective (HR) mirror coating. The latter is also known as anti-reflective (AR) coating, commonly used on eye glasses.

Optical thin films includes (1) metal coating and (2) dielectric coating. Dielectric coating has a variety of functions such as wavelength selective high-pass filter, low-pass filter and band-pass filter. Fiber-optic communication and the related products have deployed the optical thin film technology.

Santec proprietary thin film technology

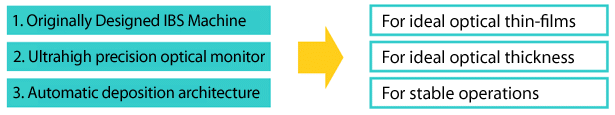

We have developed advanced thin film technology for a variety of application products as a core technology. There are three major targets to achieve, that include an ideal thin film property, ideal deposition thickness and stable process. Some examples are shown as below.

Introduction of Grand-Ex Coating Technology

An advanced coating technology so called “Grand-Ex coating technology” has been developed at Santec. The coating technology has three unique features:

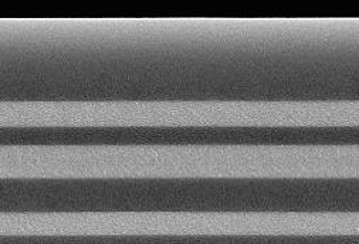

Our originally developed ion-beam sputter (IBS) coating machine (Figure 2) enable us to achieve an ideal thin film property, an ideal deposition thickness as designed and stable processing. A cross section of a multi-layer dielectric thin film taken by an electric microscope shows an ideal uniform amorphous structure (Figure 3).

Introduction of Thin-Film Coatings

Below are some examples of coatings developed by Grand-Ex technology. 1. Ultralow reflection coating (Super-AR coating) 2. Ultimate wavelength selective edge filter (Super-PON filter).

1. Ultralow Anti-Reflection Coating (Super-AR coating)

Conventional AR coating can suppress surface reflectance to 0.2%. Super-AR coating can suppress as low as 0.01%.

(a)

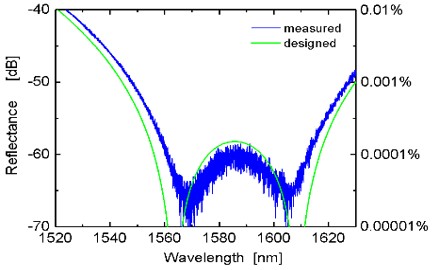

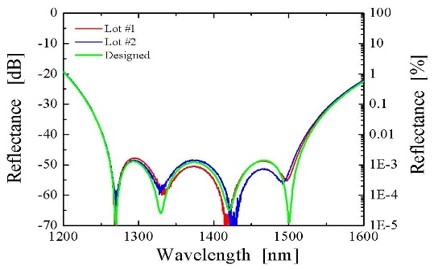

Figure 4(a) shows a super-AR coating consisting of 2 layers. A narrow wavelength band has

minimum residual reflection. Generally, this 2 layer coating is called “V- Coating.” The measured curve (blue line) shows good correlation with the design (green line).

(b)

Figure 4(b) shows a super-AR coating consisting of 4 layers. A wide band has minimum residual reflection. Generally, this type of 4 layer coating is called “W-Coating.” The measured curve (blue line) shows good correlation with the design (green line).

(c)

Figure 4. Super-AR coating

Figure 4(c) shows a super-AR coating consisting of 8 layers. A super wideband of 200 nm has minimum residual reflection. The measured curve (blue line) shows good correlation with the design (green line).

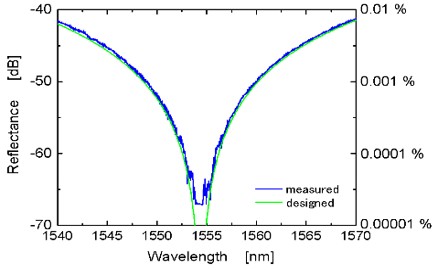

2.Ultimate Wavelength Selective Edge Filter (Super-PON filter).

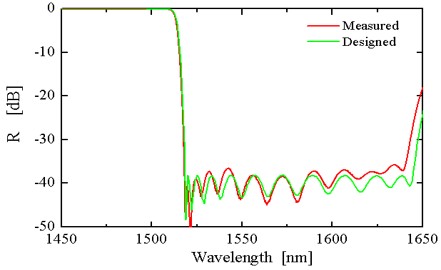

Next generation WDM-PON systems can deploy high signal isolation ONU (Optical-Network Unit) as high as 30 dB. Conventional ONU uses multiple filters to achieve high isolation. Our super-PON filter achieves sufficient signal isolations with a single unit. Efficient signal isolation of 35dB in reflection and transmission are available.

(a)

Figure 5(a) shows a reflective spectrum. A super-PON filter consisting of 118 layers. A super wideband at 1525 nm ~ 1640 nm has an ultimate low reflectance of -40 dB (0.01%). The measured curve (red line) shows good correlation with the design (green line).

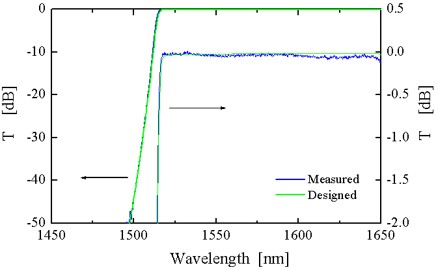

(b)

Figure 5. Super-PON filter

Figure 5(b) shows a transmittance spectrum. The measured curve (blue line) shows a good correlation with the design (green line).

The highest performance is only available at Santec. Santec’s aim is to contribute to our society with our optical coating technology.