Performance and Innovation

MEMS

Here to view our Variable Attenuators

What’s MEMS ?

MEMS devices are very small mechanical components that are electronically driven. They contain moving parts which are typically between 1-100 micrometers in size. A variety of materials can be used, but most devices are commonly made of silicon. This is then patterned and etched using similar technology to that developed for the microelectronics industry. In contrast to conventional machining processes, such as drilling and milling, the highly precise semiconductor process can produce reliable devices, in large volumes at very low cost. MEMS technology was originally developed in the late 1980’s and can be found in a wide range of commonly used products, such as flow sensors, accelerometers used in automobile airbags, and TV games that detect motion. Miniature microphones used in PCs and mobile phones are also made using MEMS.

Santec proprietary MEMS technology

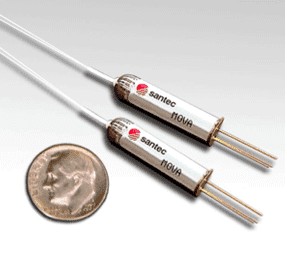

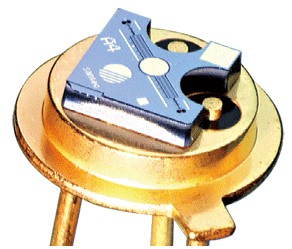

Adjustment of optical power is one of the basic functions required in a modern telecommunications system. It can be likened to changing the resistance in an electrical circuit. This function has traditionally been achieved using a mechanical component called a Variable Optical Attenuator (VOA) (Figure 1). Santec has used MEMS technology to create a mirror that tilts when an electrical voltage is applied. The degree of tilt determines the amount of light transmitted by the component. Santec’s unique design, using an asymmetrically driven parallel plate tilt-mirror created a component with a simple design that is extremely stable and reliable in operation (Figure 2). This design has been mass produced and has been installed by our customers in telecommunication systems all around the world.

Figure 1

Figure 2

MEMS device application

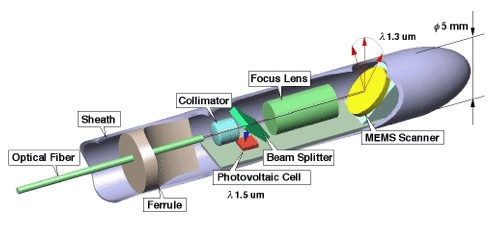

Recently, we have also been applying our MEMS technology to create components for medical imaging applications. Figure 3 shows the design of our endoscopic probe that uses a MEMS scanning mirror to scan a laser beam and capture an image. Combined with Santec’s OCT technology, this device is being applied to gastrointestinal and urological imaging as an alternative to biopsies in the detection of cancer and other diseases.

Figure 3