Outstanding Performance

Pioneering a New Frontier in Laser Processing

with the 1 kW Power Handling Spatial Light Modulator (SLM)

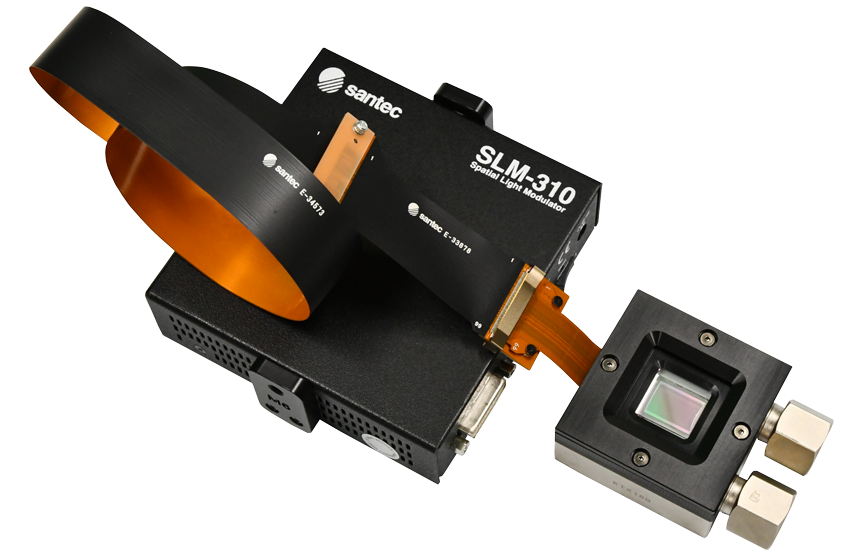

Santec has recently developed the SLM-310, a spatial light modulator (SLM) designed to withstand optical power levels up to 1 kW in the near-infrared (1 µm) range. This product was developed to meet the growing demand in industrial applications such as laser processing and metal 3D printing, where high-power lasers are increasingly used for beam shaping.

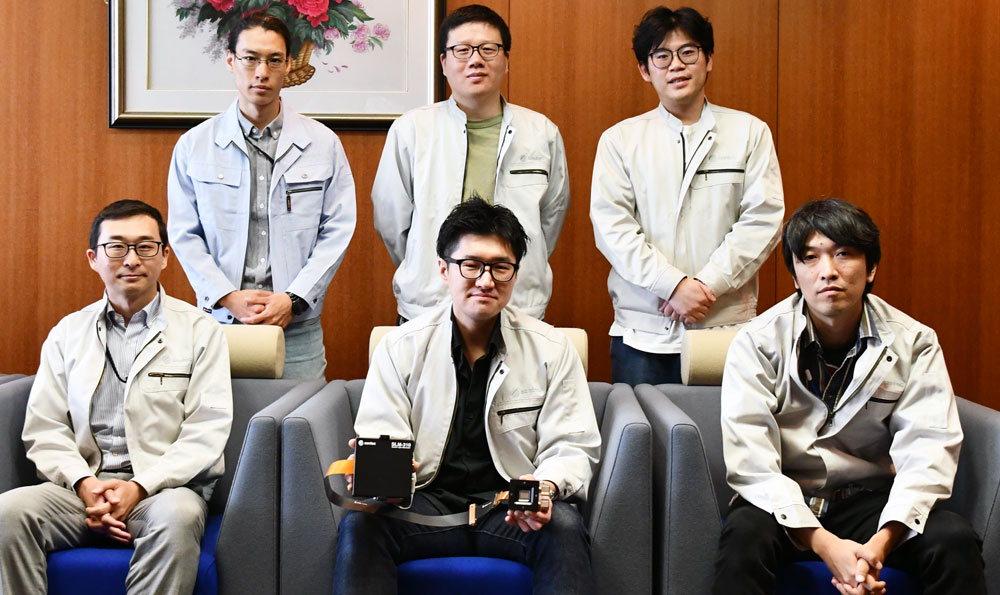

We spoke with the engineers behind its development to learn more about the challenges they faced and the innovations they introduced.

A New Opportunity Born from the Field

Today, laser processing systems equipped with galvanometer scanners are widely used in applications requiring high-speed, high-precision material processing. This method employs mirrors (galvo mirrors) mounted on galvanometer motors to rapidly steer the laser beam, enabling efficient processing across a broad range of materials—from metals to resins. As a result, it has become a standard technique within the industry. However, in recent years, end users have begun to raise the following concerns:

“Each time the processing conditions change, we have to reconfigure the laser setup, which takes time.”

“When processing over a wide area, the beam shape can vary, leading to inconsistent quality.”

Indeed, adapting the beam pattern to suit different targets or processing requirements often involves physically replacing diffractive optics or lenses—an added burden in terms of both time and operational cost.

As demand grows for processing increasingly complex geometries and a wider variety of materials, the ability to support high-power laser systems has become more critical than ever. In this context, spatial light modulators (SLMs) have emerged as a compelling alternative. By enabling software-controlled beam shaping and irradiation pattern adjustments, SLMs eliminate the need for frequent hardware changes, offering significantly greater flexibility.

However, conventional SLMs have typically lacked the robustness to withstand kW-class laser power, limiting their deployment in industrial applications such as laser processing and metal additive manufacturing.

Our development team set out to overcome this challenge—to engineer an SLM truly capable of operating in high-power environments and unlocking new possibilities in next-generation laser systems.

Development Concept

Our goal was to develop a 1kW Power Handling LCOS spatial light modulator, unlike anything that had come before.

The 1 µm wavelength range is widely used in industrial laser processing due to the popularity of fiber lasers, which offer a favorable balance of performance, cost, and availability. With this in mind, the SLM-310 was designed with a strong focus on real-world industrial environments.

The Challenge of 1kW Laser Durability

Achieving compatibility with high-power lasers required a complete rethink of three critical factors: heat generation, heat dissipation, and thermal resistance. From designing an optimized cooling structure to selecting thermally conductive materials and liquid crystal components suitable for high-power use, we reengineered the SLM from the ground up.

“With our previous designs, the liquid crystal would’ve been damaged at such power levels. But this time, the heat generation was surprisingly well controlled.”

One of the engineers even joked that the initial test results were so unexpectedly favorable, they double-checked the measurements in disbelief.

Interestingly, a major breakthrough came from an accidental mistake:

“One team member mistakenly used the wrong material. But when we tested it, the results were unexpectedly excellent.”

Through a combination of serendipity and relentless experimentation, we succeeded in developing a spatial light modulator that offers both 1kW-class optical durability and high modulation performance. After conducting more than ten rounds of long-duration reliability testing and continuous improvements, the team achieved a robust, stable device suitable for harsh high-power environments.

Speed, Flexibility, and the Future of Laser Processing

Unlike conventional systems, spatial light modulators allow for real-time, software-based control of beam shape and irradiation patterns—enabling rapid switching with no mechanical adjustments. This makes it possible to simultaneously process multiple areas in a single shot, reducing takt time and improving throughput. Furthermore, by enabling pinpoint control over laser energy distribution, the SLM can concentrate heat precisely where it's needed. This minimizes spatter and contributes to greater process stability and quality. The limited number of moving parts also improves the overall durability of the system. We may be approaching a future where laser processing systems are designed with SLM integration from the outset.

“Ultimately, we’re planning for mass production with OEM supply in mind. We're aiming not only to serve research institutions and universities, but to achieve widespread adoption in industrial manufacturing.”

Tackling the Unknowns of the Factory Floor

With this development, we have finally brought an end to the long battle against heat. The project was the result of diverse expertise and collective effort.

“Honestly, we still feel some uncertainty—like how it will perform after thousands of hours in actual production environments. But every improvement we made gives us confidence.

We’re also sure that users in the field will come up with new ideas we haven't even imagined. We look forward to working together to refine it based on real-world feedback.”

And what was their first impression when holding the completed product?

“It’s heavy! I mean physically heavy,” He laughs. “But that just shows how much is packed inside—technology, effort, and passion.”

The new SLM-310 unlocks unprecedented freedom in beam control—and represents a decisive step toward reshaping the future of laser processing with the power of light.

Santec remains committed to advancing manufacturing innovation through the development of optical solutions at the cutting edge of technology.